Solco Gas Protection System Overview

As demand for housing continues to increase, so does the pressure to develop on brownfield and other potentially dangerous land. Any buildings constructed on or near gas contaminated land face a genuine risk of hazardous gases penetrating up through the floor. If not allowed to escape, these gases can build-up and concentrate to either asphyxiating or even explosive levels, causing a significant health and safety risk. The 1991 Building Regulation C2 requires that the occupants of buildings should be protected from the effects of gaseous contamination in the ground. Importantly, the choice of membrane should not only be down to its gas permeability, it should also be selected according to its ability to withstand the construction process.

Solco’s Gas Protection membranes comply with all the latest guidance on the use of gas resistant membranes. hey are BBA Certified for use in a range of situations and provide outstanding protection against hydrocarbon and VOC vapours, as well as common ground gases such as carbon dioxide, methane and radon. These membranes also offer exceptional robustness and long-term reliability.

Hydrocarbon Barrier offers a safe solution for the protection of buildings and occupiers against all levels of hydrocarbons, methane, carbon dioxide and radon ingress. Typically, these are sites previously used as petrol stations, coalfields landfill sites, contaminated industrial sites, Fracking sites, and heavily contaminated sites. The membrane also acts as a damp-proof membrane. Due to the flexible nature of our hydrocarbon Barrier’s. They also provide a flexible membrane suitable for various applications unlike rigid HDPE rich membranes.

Solco membranes are designed to withstand the most aggressive environments. Testing has been completed in accordance with BS8485:2015 and C748 to determine the permeation rates for Methane, Carbon Dioxide, and a range of VOC’s. Immersion testing has also been completed to for Chemical Resistance to EN 14414 and EN 14415. The level of testing is to prove the suitability for these challenging environments.

Solco can also supply a Liquid Gas Barrier which can be used to protect most building surfaces form the effect of liquid and water vapour, carbonation and to act as a gas barrier to prevent the ingress of Methane, Carbon Dioxide, Radon and VOC’s. As the product is a barrier to moisture it can be used as a DPM on floors and walls. Solco’s Liquid Gas Barrier is tested to meet the requirements of BS8485:2015.

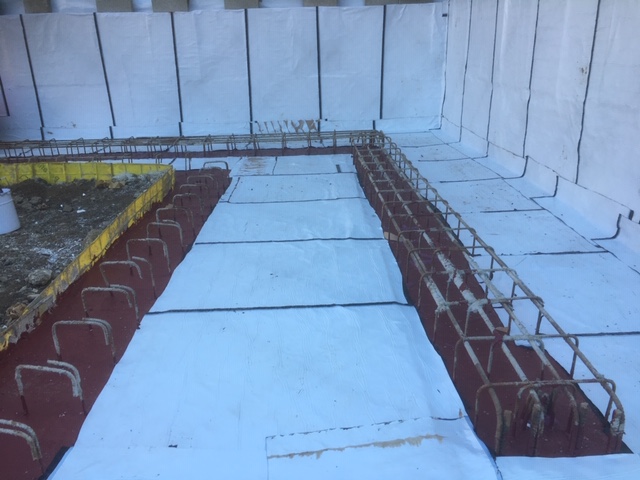

Solco’s Gas Protection System(s) also includes a range of accessory products to the Barrier System including, Geotextiles for protection of the Gas Barrier, Void Ventilation Geocomposites, DPC’s and self-adhesive products for complex installations.

Description

| Gas & Waterproof Product Selector | Radon | Bulk Ground Gas to NHBC (Amber 1) | Carbon Dioxide & Methane | Hydrocarbon / VOC | Hydrocarbon / VOC | Waterproof | Agrément Certificate |

| BRE211 | BS8485+A1:2019 (Amber 2) | Vapours – C748 | Immersion – C748 | to BS8102 | |||

| Solco TS Amber 1 Radon Membrane | ✓ | ✓ | BBA | ||||

| Solshield High Performance DPM | ✓ | BBA | |||||

| Solshield Reinforced Gas Barrier | ✓ | ✓ | BBA | ||||

| Solshield Ultra Gas Barrier | ✓ | ✓ | ✓ | ✓ | BBA | ||

| Solshield Flexible Hydrocarbon Barrier | ✓ | ✓ | ✓ | ✓ | ✓ | ||

| Solshield CT Bond Crystalline (NEW) | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | BDA (Applied) |

| Solshield CT Bond Pre (NEW) | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | BDA (Applied) |

| Solsheet Self-Adhesive Membrane | ✓ | ✓ | ✓ | BBA | |||

| Solsheet GR Self-Adhesive Membrane | ✓ | ✓ | ✓ | ✓ | ✓ | BBA | |

| Solseal Flexible Liquid Membrane | ✓ | ✓ | ✓ | ||||

| Solseal Liquid Gas Barrier | ✓ | ✓ | ✓ | ||||

| Solseal PB-2K | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | |

| Solcourse HP DPC | ✓ | ✓ | BBA | ||||

| Solcourse GR DPC | ✓ | ✓ | ✓ | BBA | |||

| Solcourse 3S DPC | ✓ | BBA | |||||

| Actitex Bentonite Membrane | ✓ | BDA |